SYSTEM OVERVIEW

The Vector is equipped with a hydraulic accumulator system. This system uses pressurized fluid stored in an accumulator to operate the boom up movement and gravity for boom down movement. This enables the boom to move up and down almost silently. A pump is not required to operate while the boom is moving. The accumulator holds enough fluid for about 4 full lifts of the boom, then it needs to be recharged with either the hand pump or electric pump.

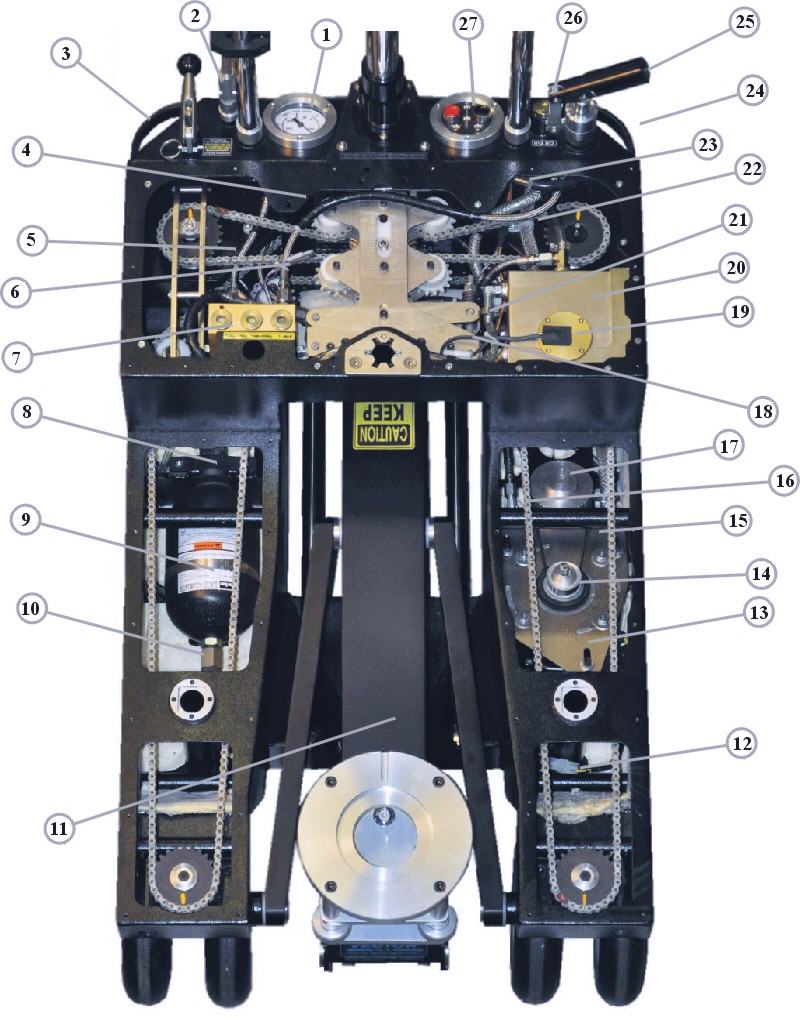

ELECTRIC CHARGING: When charging the system with the electric pump, the Motor/Pulley(14) turns the Pump/Pulley(17); Oil is drawn out of the Oil Tank(20) then passing through the Pump and the Check Valve Assembly(16). (The Check Valve prevents oil from moving backwards when the pump is shut off.) The oil is sent under pressure into the Manifold(7), where it is then sent to the Pressure Gauge(1) and to fill the Accumulator(9).

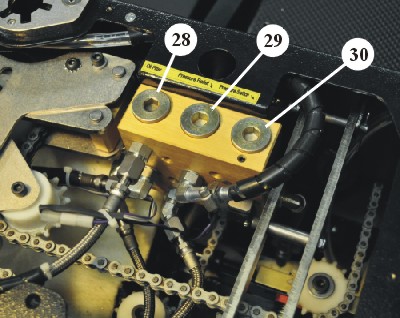

Within the Manifold, oil is sent through the Filter(28), to the Pressure Relief Valve(29) and the Pressure Switch(30). When the pressure reaches the specified psi, the Pressure Switch shuts off the motor. The Motor can also be shut off at any time with the Stop Button, or if the oil level is too low, the Oil Level Switch(19) will stop the motor, and the Oil Light on the Electric Control Panel(27) will come on. The Pressure Relief Valve is a safety feature to prevent excessive pressure in the system.

Figure H1

Figure H2

28 Filter / Plug

29 Pressure Relief Valve / Plug

30 Pressure Switch / Plug

< Previous Page --- Next Page >

Copyright © 2019 Premier Studio Equipment, Inc.